3D Photopolymers

Stereolithography (SLA)

Ref : Tassilo Moritz, Saeed Maleksaeedi, 4 - Additive manufacturing of ceramic components, Editor(s): Jing Zhang, Yeon-Gil Jung, Additive Manufacturing, Butterworth-Heinemann, 2018, Pages 105-161,

The earliest 3D printing technologies were established in 1986 with their ability to produce high-precision components and smooth surfaces, making them suitable for immediate prototyping. This technology employed photopolymers and high-intensity UV lasers to initiate chemical reactions that resulted in solidified objects.

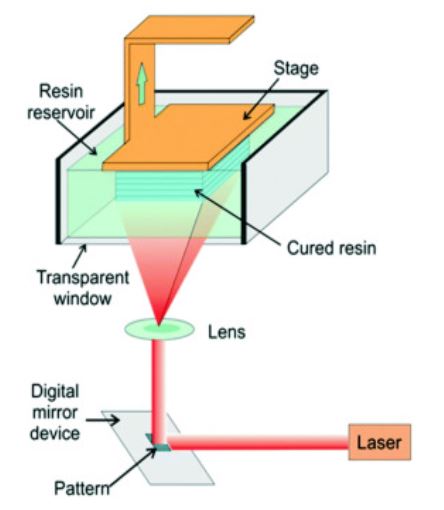

In recent years, substantial advancements have been made in 3D printing technology, particularly with the introduction of Digital Light Processing (DLP). Both SLA and DLP systems operate on the principle of projecting light onto a tray filled with photosensitive resin. Upon exposure to light, the resin cures only in the illuminated areas, enabling the formation of three-dimensional shapes.

The principal distinction between SLA and DLP lies in their respective light sources and processing speeds. The SLA system utilizes a laser light source, where the machine continuously traces laser lines across the resin surface to form the desired object. Conversely, the DLP system employs a projector to cast an image onto the resin tray, allowing for the simultaneous curing of an entire layer. This results in significantly reduced printing times, as it obviates the need to draw each line individually.

These advanced printing technologies are predominantly utilized for the production of small, intricate components that require high resolution, rendering them particularly suitable for applications in decorative arts, industrial manufacturing, and medical modeling.